Screws scrolls and reciprocating compressors are positive-displacement systems and their efficiency is sensitive to lift. Unlike centrifugal chillers and as a result of its positive displacement design a screw chiller applied for non-standard lift conditions can be tested at AHRI conditions of 51F of lift.

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

A two-inch Schedule 40 pipe.

. Last week we revealed the five priorities of saving energy. I figured this counterflow heat exchanger design would be perfect for my counterflow-HERMS brewery due to the cleaning access. Some chille rs can tolerate flow-rate variationsas much as 50.

Chillers are piped in series counterflow if one surges it is likely that the adjacent centrifugal chiller will. Series chiller VPF flow relationship. Section 3 Chiller Components Types Efficiency Improvement Advantages Parallel Reference Smaller and simpler plants Series 3-4 Better part load pump energy Series Counterflow 5-7 Best chiller energy performance Upstream chiller high-side can not perform as downstream one low-side.

Additionally since it only utilizes straight lengths of copper it is easily cleaned and inspected. Advanced high efficiency two-stage compressor design specifically for HFC-134a. Series counterflow chillers can be 5 to 7 more efficient than a single chiller at design conditions and save up to 20 of chiller energy annually.

In a SCF configuration the chiller making the coldest chilled water also gets the coldest condenser water. By Jeff Ihnen May 22 2017. The water in is basically the exit from my immersion chiller with the assumption that the chiller will sit in an ice bath in summer months.

However the condenser pump is sized for the entire system flow in this case 2400 US gpm and this pump must operate whenever any chiller operates. Now Variable Primary Only Series Counterflow This configuration improves overall chiller efficiency by reducing the lift on the compressor. That is not less than the cooling set point.

Design flow gpm 100 2 chiller 1 chiller system load flow 2500 2000 1500 1000 500 0 10 20 30 40 50 60 70 80 90 100 capacity tons design flow gpm min. Configuring water-cooled chiller plants in a series counterflow SCF arrangement splits the lift between two machines to enhance the operating efficiency of the plant. Pumping energy can be higher than parallel arrangement.

Now when series counter-flow is chosen from a plant design we take the same two 500 ton 1758 kW chillers typically they are identical in configuration and re-pipe the flow of water differently. Compared with parallel arrangements. Besides for plate chillers.

The water out is a camlock post. Chiller full load efficiency ratings are usually given in the form of. 4 Chiller System Design and Control SYS-APM001-EN Primary System Components Some chiller controls can accommodate very little flow variation during machine operation2 Other more sophisticated chiller controls allow some flow variation.

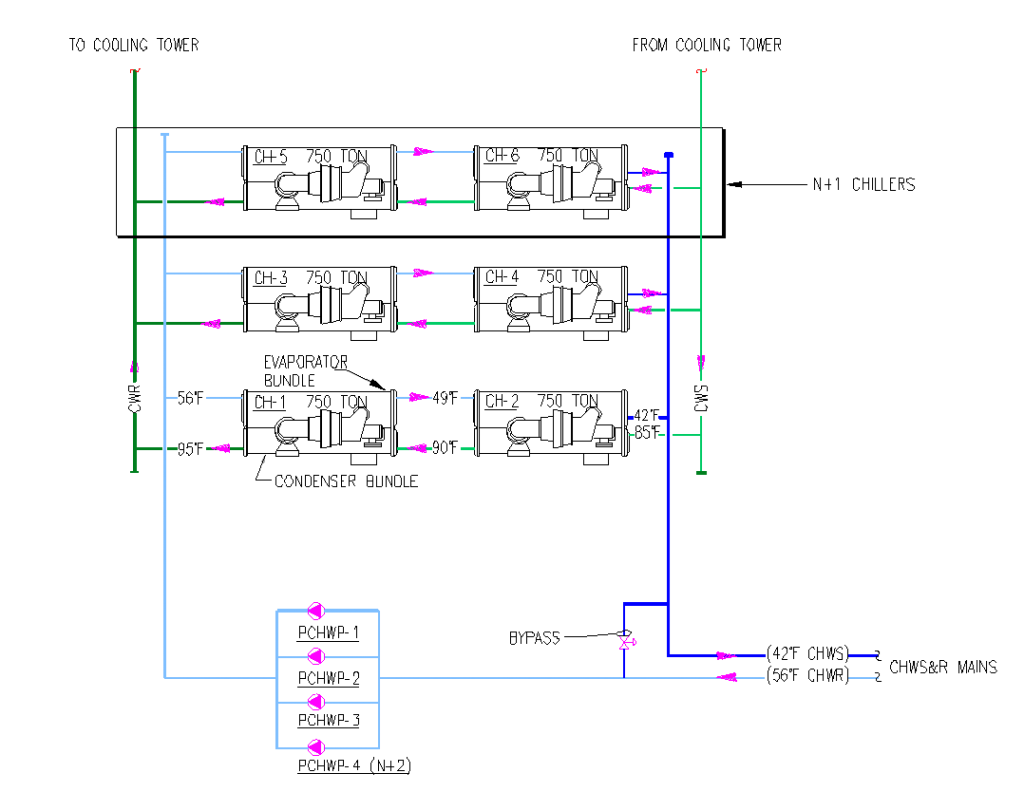

60 44 Evaporator 85 30 gpm per ton in Condenser Energy Efficiency a priority Any one chiller can provide. Series Counterflow Chiller Arrangement Variable Primary Only. Series arrangements of chiller evaporators have been used when prudent in many ap-plications7 16 However the chilled-water plant design that was selected for this project not only arranges the evaporators in series but also arranges the condensers in series using a counterflow configuration see Figure.

I used this because I happened to have a spare post and a garden hose camlock adapter left over from my plate chiller build. Application Guide AG 31-003-4 3 Introduction Using chilled water to cool a building or process is efficient and flexible. Figure 41 - Series Counterflow System Design.

One of the many system modifications that has the ability to improve efficiency greatly is the use of a chiller piping strategy called Series Counter-Flow SCF. Two 525 ton chillers in Series Counter Flow One chiller meets 525 ton critical load Running redundancy Variable primary pumping system. Ad We Also Supply and Install All of Our Chillers to Meet Your Specific Needs.

Consequently the ASHRAE 901 standard. The heat reclaim chiller would continue to control the hot. A 1000 ton chiller has a motor rated at 700 hp.

However the condenser pump is sized for the entire system flow in this case 2400 US GPM and this pump must operate whenever any chiller operates. The counterflow chiller setup consists of a set of tubes of different sizes through which the heated wort and cooling water flow in opposite directions to facilitate brew temperature optimization. Some chillers can tolerate flow-rate variations of as much as 30 percent per minute or greater while others can only tolerate up to 2 percent per minute.

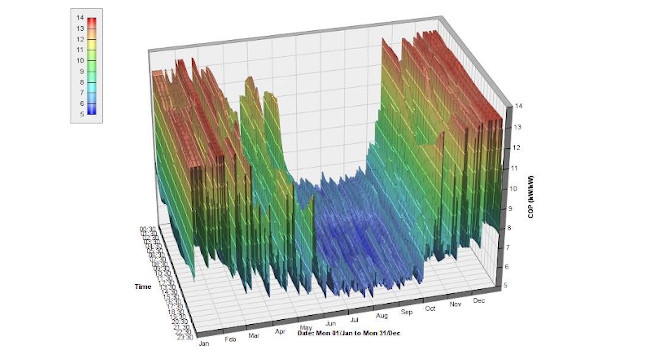

19XR Two-stage Centrifugal Chiller Series Counter Flow Application Industry-leading Efficiency 19XR chillers can achieve up to 66 full load COP R and 75 IPLVIP without VFD or 110 IPLVIP with VFD at AHRI conditions. Improving the chiller performance has immediate benefit to the building operating cost. The operation of an immersion chiller is simple by design.

CHILLER PLANT FLOW DESIGNS. Choose From Over 100 Types Of Hops 140 Types Of Grains And 230 Beer Recipe Kits. Slow it down set it back temperature etc Reduce waste.

This document evaluates the impact of SCF on efficiency while keeping in mind what it requires on the building controls side as well as plant design piping arrangement. Figure 1 shows a simple two chiller series counterflow arrangement and the associated reduction in effective compressor lift. Pump selection crucial and avoid oversizing as they.

14 TD ratio Include the requirement to submit chiller minimum and maximum rated flows as a line item in the bid. Offers The Largest Selection Of Brewing Supplies To Home Brewers Across The USA. Series counter flow chillers can be 5 to 7 more efficient than a single chiller at design conditions and save up to 20 of chiller energy annually.

As the condenser water enters chiller 1 CH-1 it will then procced to chiller 2 CH-2 directly after in the same direction. Flow gpm turndown 2 chiller. Chillers are often the single largest electricity users in a building.

Ad Compare Prices on counterflow wort chiller in Home Garden. The water is a little more involved. It is a design that appeals to DIYers because it does not require any bending of copper.

Design in Series. Heat elimination using a counterflow chiller is achieved using a series of. The heat reclaim chiller s low source protection feature will ensure that chilled water is provided at a tem.

If additional cooling is needed to maintain temp the series counter-flow chiller plant would be energized. Some chiller controls can accommodate very little flow variation during machine operation2 Other more sophisticated chiller controls allow some flow variation. Because series-series configurations reduce lift they also reduce compressor energy use.

Now one machine will cool the water from 56 F to 49 F and the.

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

How Do I Model Series Counterflow Chillers In Trace 700

Ideal Counter Flow Chiller Home Brewing Beer Home Brewing Equipment Beer Brewing Equipment

Copper Counterflow Chiller Build Home Brewing Craft Brewing Brewing Equipment

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

The Benefits Of A Series Counterflow Chiller Arrangement Tlc Engineering Solutions

Zchiller Wort Chiller First Looks Brewing Supplies Nano Brewery Beer Jockey Box

Consulting Specifying Engineer Series Counterflow Chiller Arrangement Benefits

0 comments

Post a Comment